Loading...

Please wait while we prepare your content

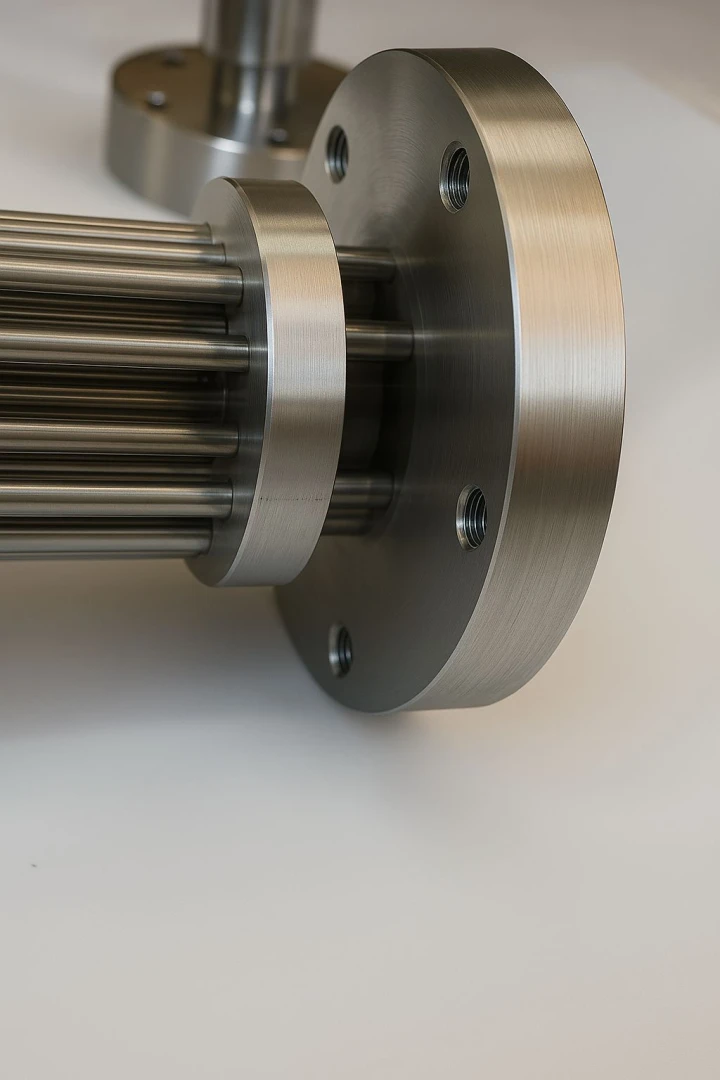

The TEE DTS heat Exchanger is a sanitary shell-and-tube heat exchanger specifically engineered for pharmaceutical water systems, including PW (Purified Water), WFI (Water for Injection), and Pure Steam (PS). Designed to meet the strictest industry standards, it ensures safe and efficient heating, cooling, sterilization, and sanitization processes in pharma environments.

Heating/Cooling of WFI, PW, and PS Sterilization loops for tanks and distribution systems Utility/product separation in critical process steps

Our Double Tube Sheet (DTS) configuration prevents cross-contamination between product and utility fluids. In the event of internal leakage, any fluid loss is externally visible, allowing immediate detection and ensuring product integrity.

cGMP compliant construction FDA and ISPE Baseline design principles EHEDG guidelines for hygienic design ASME BPE standard adherence

Contact surfaces: AISI 316L stainless steel Internal surface finish: -Electropolished Ra 0.4 µm. -or Mechanically polished Ra 0.5 µm. GTAW orbital welding Pickled & passivated surfaces PTFE gaskets Insulated & cladded with AISI 304 stainless steel (satin finish) Fully pressure-tested and leak-inspected

The TEE DTS heat Exchanger is engineered to deliver high thermal performance and reliability in critical pharmaceutical processes. It features: Heat Transfer Area: From 0.1 m² to 8.5 m² Design Temperature: Up to 150°C Design Pressure: Up to 10 bar Flow Capacity: Ranges from 2,000 to 20,000 liters per hour

Drainable, cleanable, sanitizable, sterilizable SCADA integration available (21 CFR Part 11 compliant) Flexible installation: vertical or horizontal mounting Cooling and heating compatible

U-Shape: Two-pass or Multi-pass Linear Shape: Single-pass or Multi-pass

Each TEE DTS heat Exchanger is delivered with full qualification documentation: Isometric drawings Welding & fabrication protocols Material certificates Borescope & leak test reports Surface finishing & passivation reports Instrumentation calibration